-

Room 101, Building 3, No. 5, 1st Road, Ludi Industrial Zone, Humen Town, Dongguan City, Guangdong Province, China

-

Call Us +86-18825501449

-

Mail Us sales@vacuum-fresh.com

Room 101, Building 3, No. 5, 1st Road, Ludi Industrial Zone, Humen Town, Dongguan City, Guangdong Province, China

Call Us +86-18825501449

Mail Us sales@vacuum-fresh.com

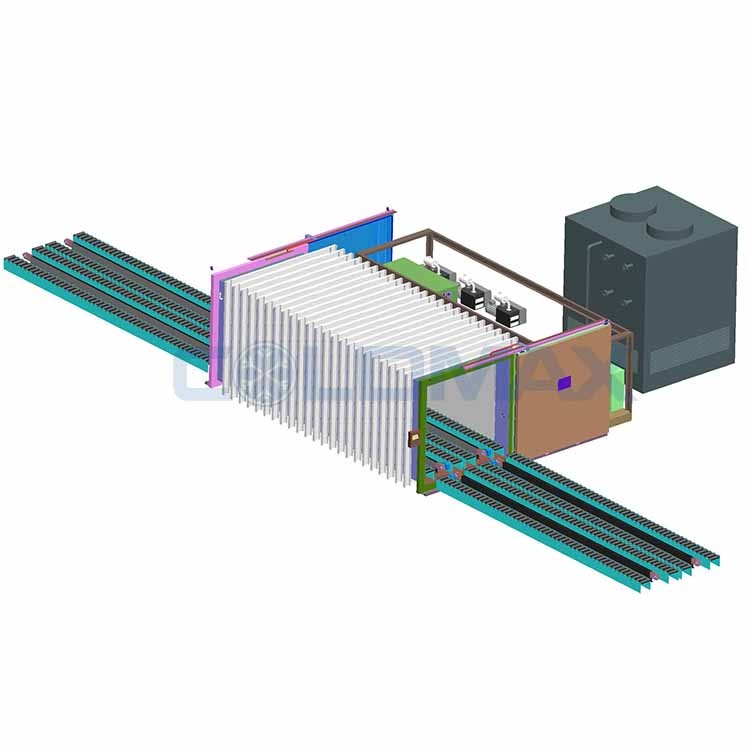

Vacuum coolers used to cool products are the best method to remove heat in the field before storage. We have developed an innovative, almost fully automatic vacuum cooling method. This requires minimal labor for the work and maximizes processing capacity for any given machine size.

We design and build based on individual needs. This allows you to choose equipment that meets specific requirements, cooling speeds and product types. We can even build in the possibility of making the cooler bigger to take into account the future growth of the company, but not to increase the initial costs of a large machine at the start.

Vacuum cooling is most effective for cooling green leafy vegetables, but some other products can be cooled with the addition of "wet" cycles. For example, broccoli can be cooled much faster in a vacuum cooler than in a cool room when cooled in a "wet" cycle.

Salad of all kinds is best suited for vacuum cooling. A typical cycle time for a salad is from slightly less than 20 minutes to maybe 25 minutes. The final temperature is usually about 0.5-2.0 ° C.

The advantage of vacuum cooling is that the field heat is removed much faster. This extends the shelf life of the product. It is suggested that the storage time is longer because the time spent cooling the lettuce decreases every hour.

Send us an inquiry now to get a quality offer! Click here to send an inquiry!