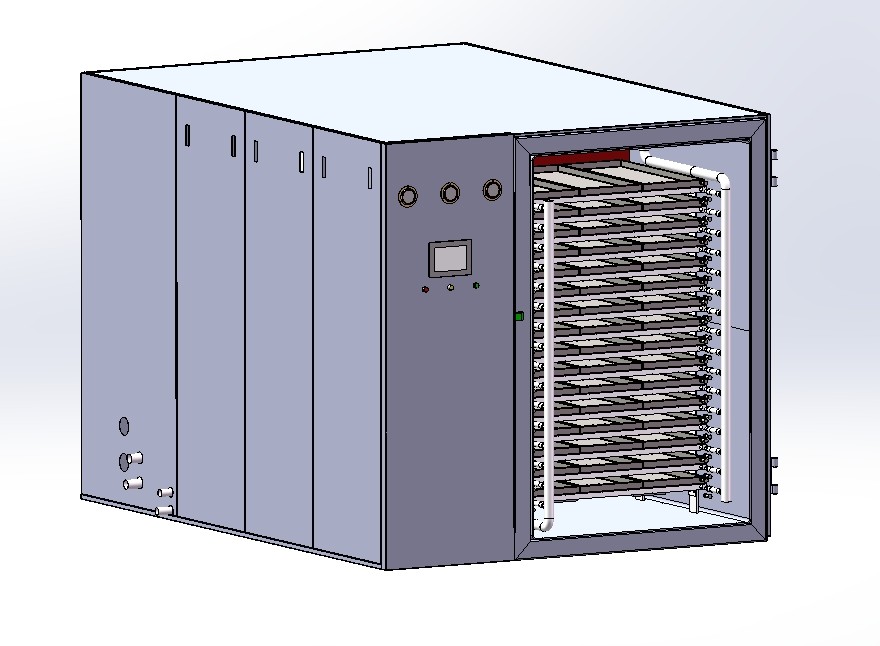

Agitated Vacuum Dryer Manufacturer

The B&P Littleford Polyphase Reactor is a single apparatus designed to handle mixing materials of varying composition that may pass through phases of liquid to doughy, granular, or powder form as they dry. They also have the combined operational features of pressure and high vacuum, with effective heat transfer (heating or cooling). Units would be built to ASME Code Standards as well as differing standards across the globe.

This Reactor operates according to the proven "fluidized bed" mixing principle whereby the materials being reacted are maintained in a mechanically fluidized suspended state, thus permitting the reacting mediums, gas-solid or liquid-solid, to achieve intimate contact with each other and the heat transfer surfaces.

Advantages Of Agitated Vacuum Dryers

The following results occur with an industrial vacuum dryer, specifically an agitated vacuum dryer:

· Controlled reaction through effective heat transfer.

· Improved reactions rate.

· Increased efficiencies of reaction.

· Ability to complete an entire process in a single unit due to the ability to remove a volatile solvent.

· Reduced levels of solvent or diluent can be used due to the mixing action and the ability to handle phase changes.

These are distinct advantages of an agitated vacuum dryer over an autoclave or slow moving ribbon vessel whereby the contact between the heating medium and the material is more by diffusion and is therefore slow, uncontrolled, and takes place at different times throughout the material. The basic design of the B&P Littleford Polyphase Reactor is a horizontal cylinder, which is top loaded and bottom discharged. There are several mixing tool styles available that radiate from a horizontal shaft which is supported by outboard bearings.

The basic mixing action may be supplemented by high speed choppers that are positioned between adjacent plows for high shear applications. The shaft seals are appropriate for the mixing process and include double-faced, balanced, mechanical seals as well as packing or lip seals. Request a quote for more information or to run your material in our Saginaw, MI Tech Center.