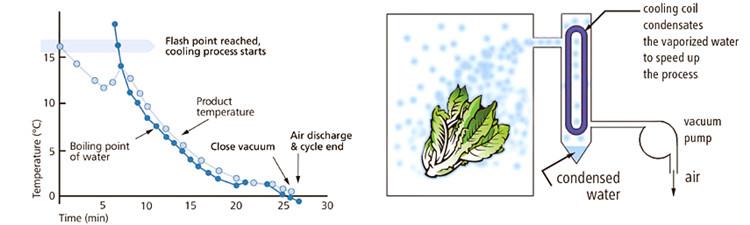

Vacuum cooler working principle

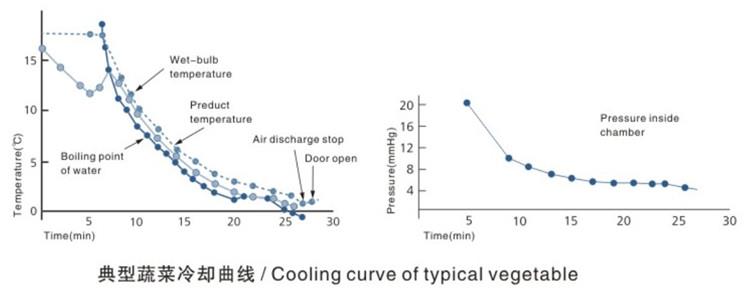

Vacuum cooling removes heat from vegetables by boiling the water contained in the vegetables. The produce is packed in a closed room and the air is withdrawn. This reduces the pressure from normal air (about 100 kPa) to a virtual vacuum (less than 1 kPa). Under these conditions, water boils below 7 ° C.

When the water in the vegetables changes from liquid to gas, it absorbs heat from the product and cools it. The vapor is removed by extracting it from the cooling disk and the cooling coil condenses it back to liquid water.

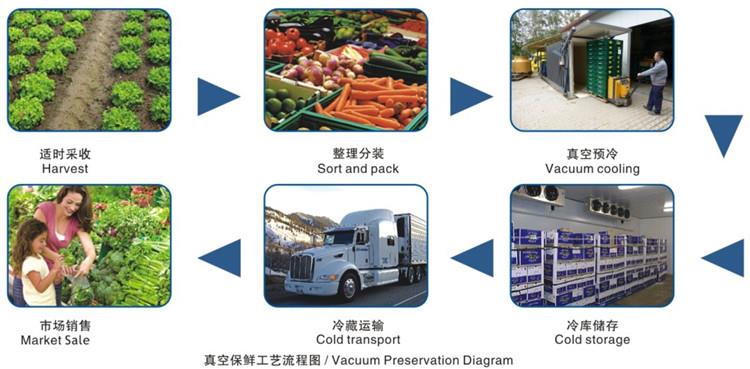

In order to cool vegetables in a vacuum quickly, they must be able to lose water easily. Therefore, vacuum cooling is very suitable for leaf products such as lettuce, green vegetables in Asia, and silver beet. In this way, products such as broccoli, celery and sweet corn can also be cooled effectively.

Vacuum cooling is not suitable for products with waxy peels or products with surface areas smaller than volume, such as carrots, potatoes and zucchini.

About every 1% of the weight of the product needs to be converted to water vapor at every 5 ° C temperature drop.

However, recent hydraulic vacuum coolers solve this problem by spraying the product with water during the vacuum process. This will reduce the loss of water to a negligible level.

Send us an inquiry now to get a quality offer! Click here to send an inquiry!