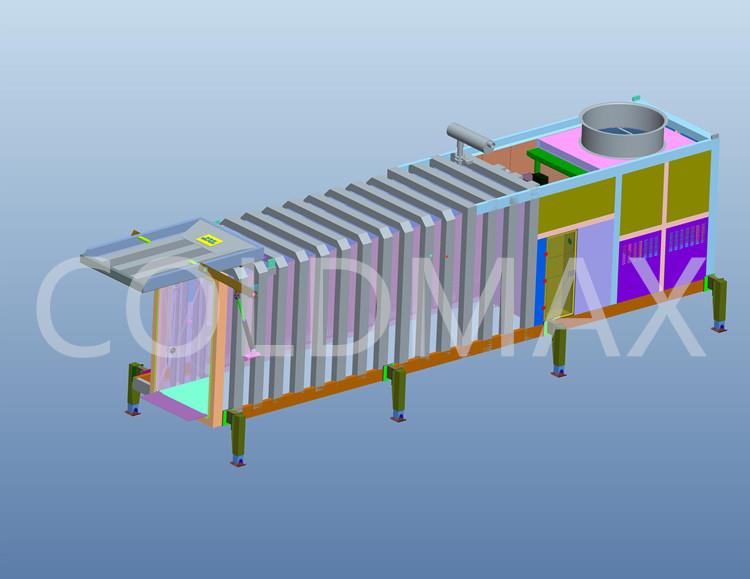

6 pallets vacuum cooler with hydraulic door

1. Language version of human-computer interface: English, Russia, Spanish and more (optional)

2. Lead time: 45 working days

3. Quality guarantee: 12 months

4. Payment way: 30% T/T as deposit, 70% paid before delivery

5. HS Code: 841869

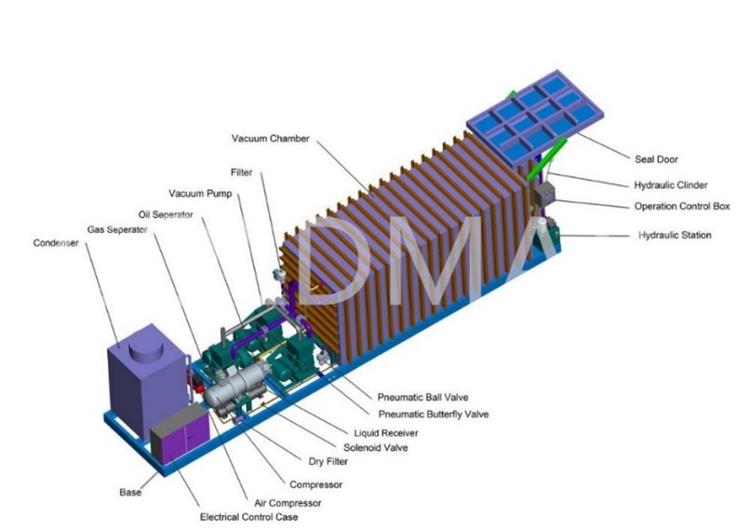

The main components of a vacuum cooler (1/2)

1. Vacuum chamber

There are 2 basically requirements for the vacuum chamber. One is size, the other one is strength.

In the one hand, the size of the vacuum chamber must be large enough to maintain the batch and work intervals for each cycle, to allow for future changes in stacking of pallets or stack sizes. We offer customized vacuum chamber sizes that can accommodate one or two rail conveyor systems. Any combination of batch size and shelf size can be suitable for our system.

In the other hand, the vacuum chamber shall be strong and hard enough to bear frequent and huge pressure differences between outside and inside of vacuum chamber (This difference means the atmospheric pressure and vacuum condition).

2. Vacuum pump

This is used for the initial evacuation of the vacuum cooler, from atmospheric pressure to the flash point of the water. After reaching the flash point, the efficiency of the pump is limited by the refrigeration unit. Generally speaking, we will adjust the size of the vacuum pump to 5-8 minutes to reach the flash point. The type of pump that is usually used is the oil sealed type or oil-less type.

3. Refrigeration equipment

Once the pressure reaches the flash point, the water begins to evaporate from the surface of the product. It is this evaporation that allows cooling. In a machine that cools, for example, 1,000 kg of product per cycle, 1,860 m3 of steam will be produced and pumped from the chamber. That is really too much for vacuum pump to deal with! Hence, a freezing coil “water catcher” is installed in the chamber to condense the steam again to water. The refrigeration unit is actually a vacuum pump. The size of the refrigeration unit has a significant impact on the duration of the cooling cycle.

Send us an inquiry now to get a quality offer! Click here to send an inquiry!