Brief description

Vacuum cooling involves reducing the pressure inside the airtight chamber. The water inside the vegetables turns into steam, absorbing thermal energy. Vacuum cooling is best suited for products that easily lose water, such as lettuce and leafy children.

Hydro-vacuum coolers add a fogging system to avoid moisture loss from the product. At the same time, hydro cooling can help cool down faster and make some compact vegetables suitable for the vacuum cooling process.

Vacuum cooling is a quick and energy efficient freshness method.

What is vacuum cooling? (In detail)

Vacuum cooling removes heat from vegetables by boiling the water they contain.

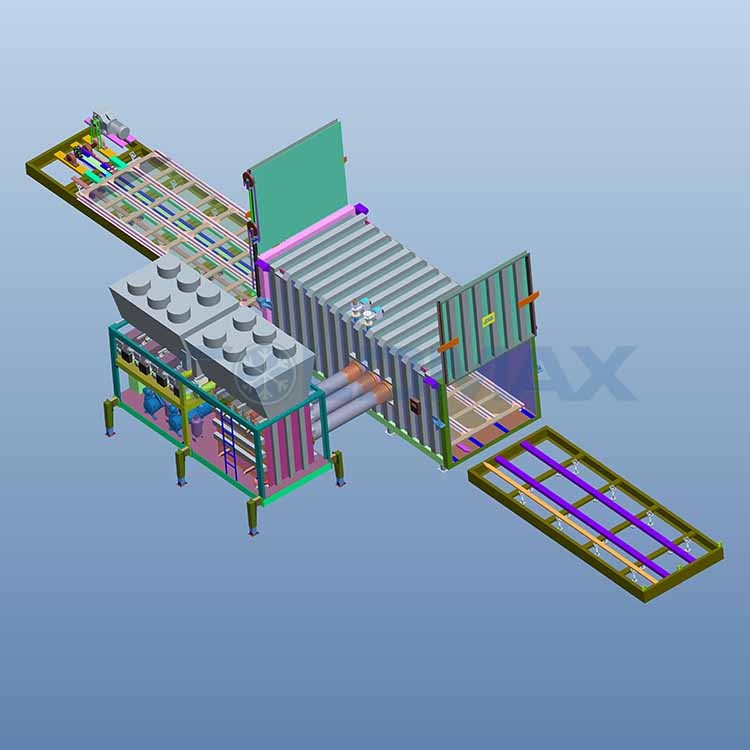

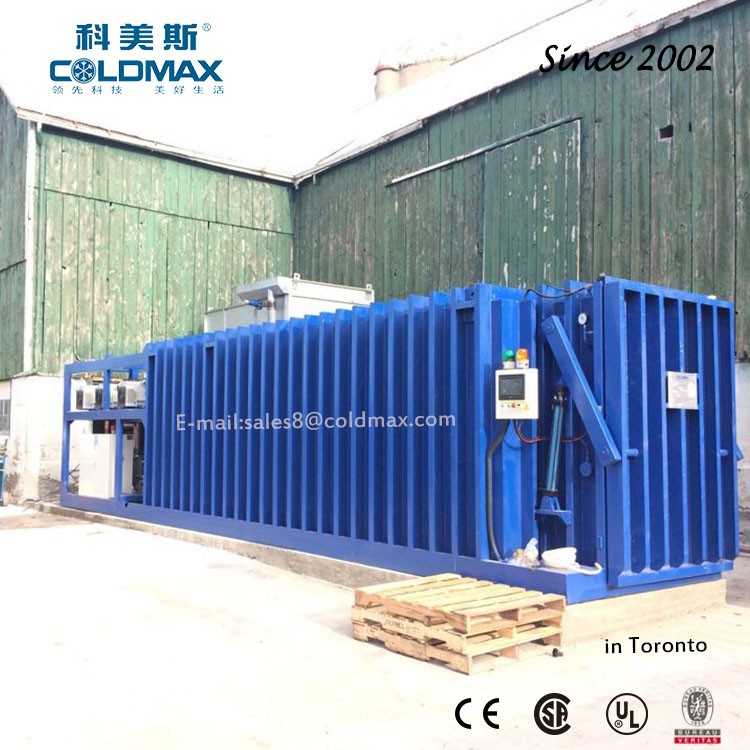

The products are loaded in an airtight solid vacuum chamber and the air is pumped out. This reduces the pressure from normal air to virtual vacuum (< 1Kpa). Under these conditions, the water boils at a temperature of < 7 °C.

As the water in the vegetables changes from liquid into gas it absorbs the heat energy from the product, cooling it. This vapor is removed by drawing it past the refrigeration coils that condense it back into liquid water.

For vacuum cooling to cool vegetables quickly, they should be able to lose moisture easily. For this reason, vacuum cooling is very well suited for leafy products such as salads, Asian greens and fresh cut flowers. Products such as broccoli, celery and sweet corn can also be effectively cooled by this method. Vacuum cooling is not suitable for products with wax peel or low surface/volume speed, such as carrots, potatoes, tomatoes or zucchini.

When the temperature decreases for every 5 °C, approximately 1% of the product weight must be converted into water vapor. However, modern hydro-vacuum coolers solve this problem by spraying water on the products during the vacuum process. This can reduce moisture loss to a negligible level.

Send us an inquiry now to get a quality offer! Click here to send an inquiry!